SSD power loss protection refers to a hardware-and-firmware safety net that helps keep an SSD from corrupting your data when power suddenly dies. Basically, it keeps an eye on the input voltage. When it detects any kind of brownout, it utilizes energy stored in capacitors on board. That additional energy lets the controller stop accepting new writes, flush volatile buffers to NAND, and finalize its internal mapping tables before everything goes dark.

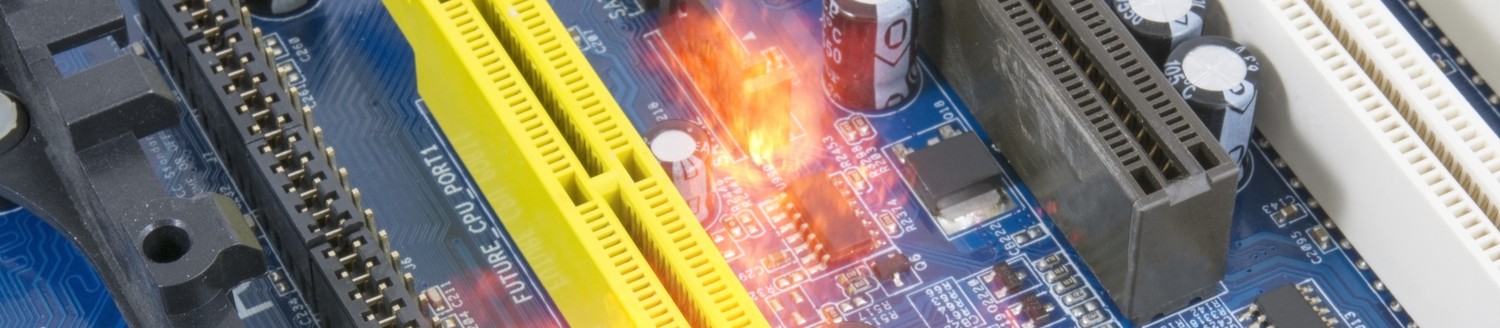

Without SSD power loss protection, a random outage can freeze the drive mid-program and leave half-written pages, broken metadata, and silent corruption in databases, virtual machines, or RAID arrays. In one USENIX FAST research, fifteen commodity SSDs had their power switched off many times. Consequently, thirteen of them lost or corrupted data. On one drive, a third of all the data saved on it disappeared after only one power breakdown.

That's the reason why SSD power loss protection is treated as a hard requirement in industrial PCs, servers, base stations, medical devices, and transportation systems. Remember that such systems witness recurrent dirty shutdowns and harsh power. Here, data loss can imply safety complexities for people, compliance incidents for you, or very expensive downtime. Vendors provide specialized PLP-enabled industrial lines to satisfy these heightened needs.

For instance, ADATA Industrial's 2.5-inch ISSS31AP SATA SSD offers 4-8 TB of storage using 112-layer 3D TLC. It also has tantalum polymer capacitors with short-circuit protection for strong PLP and LDPC ECC, a DRAM buffer, and wide-temperature support from -40°C to 85°C to keep data safe even when working with demanding embedded and networking workloads.

Under the hood, SSD power loss protection begins with a bank of tantalum or polymer capacitors that are behind the PMIC and act like a UPS. They hold just enough energy to keep the controller and DRAM alive for a few milliseconds once input voltage collapses. When the PMIC detects the rail dropping below a threshold, it asserts a pFail signal to the controller. That blocks new host writes, snapshots Flash Translation Layer metadata in DRAM, and begins flushing dirty cache lines and in-flight user data down to NAND in a strict and preplanned order.

At the same time, firmware runs an explicit shutdown path that finalizes mapping tables, writes journal or commit records, updates CRC tags, and marks each page as either completely valid or safely rolled back. Henceforth, the FTL can restart in a clean state. In contemporary designs, this becomes tight choreography between controller, Power Management IC, and firmware:

Keep in mind that real SSD power loss protection is always the combination of strong hardware capacitance and intelligent recovery algorithms, not simply "a few caps on the PCB."

An example is ADATA Industrial's IM2P41B8P, a PCIe Gen4x4 NVMe M.2 2280 SSD that combines 112-layer 3D TLC NAND, a DRAM buffer, tantalum polymer PLP capacitors, LDPC ECC, RAID engine, end-to-end data path protection, and AES-256 plus TCG OPAL 2.0 security. That makes its PLP architecture suited to 5G, IoT, automation, and transportation deployments.

At the simplest level, firmware-based PLP is logic in the controller that tries to keep things consistent if power cuts out. It uses ordered writes, copy-on-write mapping tables, and journal-style structures. So, metadata can be rebuilt from NAND after a crash. The SSD also tags data in spare bytes, which lets the firmware reconstruct the mapping table on the next boot instead of trashing the file system. This SSD power loss protection is cheap and helpful. But it is still best-effort because any data sitting only in DRAM right before the outage can disappear.

Hardware-focused designs take SSD power loss protection to a whole new level. The drive adds capacitors with a fast voltage-detection circuit on the power rail. Thus, the controller gets a clear signal and a guaranteed time window when power droops. In that window, it can move buffered data and critical metadata into NAND instead of leaving half-finished writes on the flash. Because the energy budget is known, engineers can size the capacitor bank for a specific worst-case write burst. That is what you want in dense enterprise or harsh industrial workloads. In the same USENIX study, only two of the SSDs were promoted with hardware power-loss protection using supercapacitors and had no integrity issues after 100 injected power faults each.

For mission-critical systems, vendors combine both ideas. So, SSD power loss protection is a layered hardware-firmware stack. ADATA's A+ Power and A+ Power Protect firmware tackle voltage-drop behavior and DRAM usage. Meanwhile, dedicated "hardware PLP" capacitor banks provide emergency energy during brownouts. In the mSATA IMSS31CP and 2.5-inch ISSS31CP, this triple methodology is combined with 112-layer 3D TLC NAND, DRAM buffers, LDPC ECC, RAID engines, and end-to-end data-path protection to keep vehicle systems, base stations, aerospace platforms, and surveillance gear running through repeated power instability.

When you're narrowing down your choices for drives, it's a good idea to compare our different PLP-enabled models side by side. For example, you could line up the 2.5-inch ISSS31CP with the mSATA IMSS31CP to see how the form factors, capacity ranges, performance, and PLP feature sets match the power-fault profile of your own industrial design.

Factories run motors, drives, and robots that slam the power rail all day. Spikes and dropouts can interrupt a write to PLC logs or recipe files. That can halt a line, force reboots, and scrap good products. A recent study of more than 3,000 plant maintenance professionals from across the world revealed that more than two-thirds of industrial companies have at least one unscheduled outage per month. The average cost of downtime is now close to $125,000 per hour. With SSD power loss protection, controllers restart and keep logs and projects intact instead of leaving engineers to rebuild broken configurations after every serious power event.

At the edge, there are gates and AI boxes in streets, skyscrapers, and distant plants. Power comes from small UPS units, solar, or unstable local grids. The nodes stream sensor data, AI results, and alarms every second. Here, SSD power loss protection keeps final samples and metadata reliable. So, dashboards and models still trust the history when the local power story is messy.

SSDs are within NVRs and DVRs in trains, buses, and smart-city poles. They capture high-bitrate video alongside GPS, braking, and diagnostic data in harsh conditions. Ignition cycles and brownouts are normal. That's why broken clips can erase key events or weaken the chain of evidence. PLP-equipped industrial SSDs close files cleanly, protect indices, and preserve usable evidence up to the last recorded frame before power disappears.

Medical devices and embedded healthcare systems follow rules for data uprightness. They hold patient IDs, imaging slices, and therapy logs that must be trustworthy for years. A mid-write outage can corrupt studies, lose alarm histories, or trigger costly retesting and compliance headaches. Thus, SSD power loss protection is treated as mandatory in medical-grade drives. It helps them finish important writes, protect audit trails, and restart in a known-good state.

At ADATA Industrial, we treat SSD power loss protection as a tightly coupled system. We combine a dedicated PLP capacitor array with tuned controller firmware. So, when the power rail drops, the controller follows a shutdown script that safely commits user data and logical-address metadata instead of leaving the flash map in an unknown state. Our power-management logic inside the controller and PMIC tracks how much hold-up energy is left and blocks late host commands. It only starts operations that can finish inside that energy window, which is how we keep user payloads and translation tables intact over long field lifetimes.

We back this design with a formal validation flow on ISSS31AP. Here, every drive goes through our SSD validation process for reliability before release. Not only that, but we also verify behavior across temperature, vibration, and repeated power cycling to mimic real industrial abuse. For projects that need strict SSD power loss protection performance, we recommend our IM2S31C8P SATA M.2 2280 PLP SSD and our 2.5-inch ISSS31AP family, which combine PLP-specific capacitors, DRAM buffering, and industrial-grade data-integrity features.

We treat SSD power loss protection as a full ecosystem that links PLP capacitors on the board with controller logic and firmware tuned to keep data consistent. Our drives are built for industrial, automotive, and embedded work. Apart from that, we verify them across wide temperature ranges, high shock, and strong vibration so that they keep running in the field. If you want to go deeper, you can explore our PLP-enabled SSD portfolio and compare models like the 2.5-inch ISSS31AP and SATA M.2 IM2S31C8P to pick the fit for your project.